- Italiano

- English

Recently added item(s)

No products

Shipping cost and the application of VAT / VAT varies according to the place of delivery

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

The ceramic production cycles: First Cycle

“… When the clay becomes smooth between hands, then I say that you can make balls or a mass as best you believe.

Now, you can work it on the wheel, or roll out it into plaster molds, depending on what you think to do.”

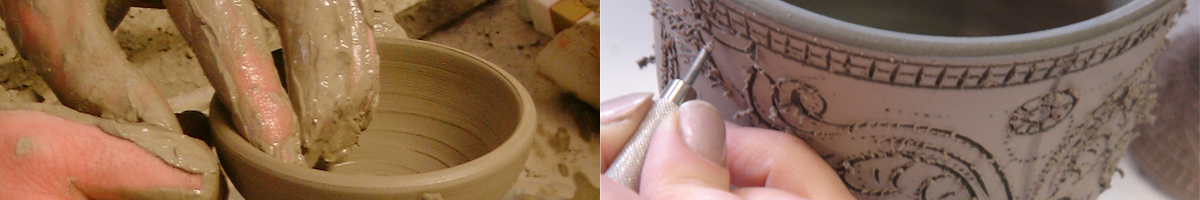

Moulding / Modelling / Casting

_Creation of the shape using methods suitable for the item to be produced. Lathe shaping enables creation of any shape or size as long as it is round. Other shapes (hexagons, ovals, complex shapes, etc.) will require various traditional procedures such as modelling by hand with plaster casts etc… The most commonly used raw material is "red clay". Apparatus used: Lathes, mother moulds, plaster casts, spatulas and various small tools, spray and powder filter booths, etc.

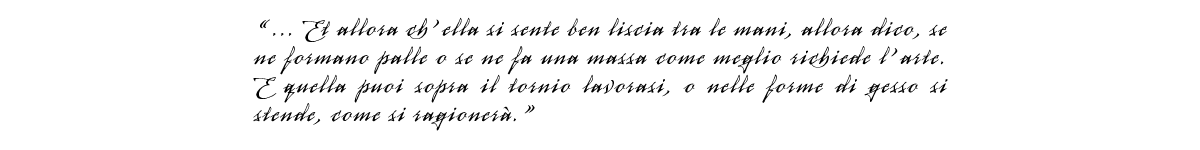

Etching / engraving

Sambuco creates a number of special decorations that require etching on the model when the clay is still soft. This process is inspired by special designs and comprises etching or engraving the object with a steel tip, all performed by hand. An example of this type of manufacturing is "Byzantine" style decoration, inspired by Byzantine era floor and wall finishes Apparatus used: Steel tips for the totally handcrafted etching, pounce-bags.

First firing "...for bisquit"

After drying the model produced at room temperature (whether it has been etched or not), the object will then be placed in a chamber for its first firing at just under 1000°C. This will take just under a day, then the chamber can be opened to remove the fired piece, called "bisquit". Apparatus used: Flame and electric kilns.

Discover the art of ceramic!

The company’s staff will be happy to guide you through the workshop, offering a comprehensive and detailed description about all phases of the ceramic’s handmande working, from the creation of the models to their exit from the kiln.

Please, contact us to book the guided visit to the workshop.